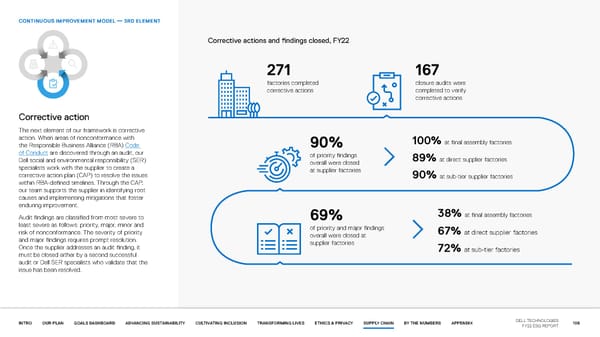

CONTINUOUS IMPROVEMENT MODEL — 3RD ELEMENT Corrective actions and findings closed, FY22 271 167 factories completed closure audits were corrective actions completed to verify corrective actions Corrective action The next element of our framework is corrective action. When areas of nonconformance with 100% at final assembly factories the Responsible Business Alliance (RBA) Code 90% of Conduct are discovered through an audit, our of priority findings 89% at direct supplier factories Dell social and environmental responsibility (SER) overall were closed specialists work with the supplier to create a at supplier factories corrective action plan (CAP) to resolve the issues 90% at sub-tier supplier factories within RBA-defined timelines. Through the CAP, our team supports the supplier in identifying root causes and implementing mitigations that foster enduring improvement. 38% at final assembly factories Audit findings are classified from most severe to 69% least severe as follows: priority, major, minor and of priority and major findings risk of nonconformance. The severity of priority overall were closed at 67% at direct supplier factories and major findings requires prompt resolution. supplier factories Once the supplier addresses an audit finding, it 72% at sub-tier factories must be closed either by a second successful audit or Dell SER specialists who validate that the issue has been resolved. INTRO OUR PLAN GOALS DASHBOARD ADVANCING SUSTAINABILITY CULTIVATING INCLUSION TRANSFORMING LIVES ETHICS & PRIVACY SUPPLY CHAIN BY THE NUMBERS APPENDIX DELL TECHNOLOGIES 109 FY22 ESG REPORT

Our purpose in action | Dell Page 108 Page 110

Our purpose in action | Dell Page 108 Page 110