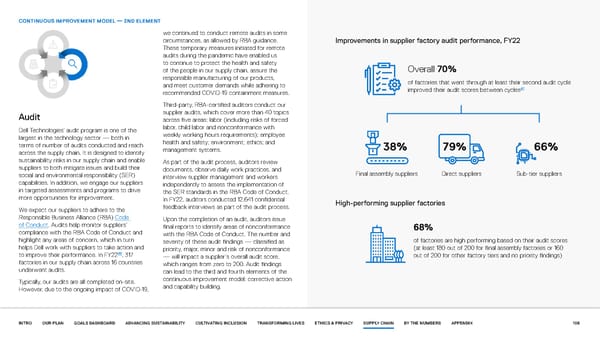

CONTINUOUS IMPROVEMENT MODEL — 2ND ELEMENT we continued to conduct remote audits in some circumstances, as allowed by RBA guidance. Improvements in supplier factory audit performance, FY22 These temporary measures initiated for remote audits during the pandemic have enabled us to continue to protect the health and safety Overall 70% of the people in our supply chain, assure the responsible manufacturing of our products, of factories that went through at least their second audit cycle and meet customer demands while adhering to 47 recommended COVID-19 containment measures. improved their audit scores between cycles Third-party, RBA-certified auditors conduct our Audit supplier audits, which cover more than 40 topics across five areas: labor (including risks of forced Dell Technologies’ audit program is one of the labor, child labor and nonconformance with largest in the technology sector — both in weekly working hours requirements); employee terms of number of audits conducted and reach health and safety; environment; ethics; and 38% 79% 66% across the supply chain. It is designed to identify management systems. sustainability risks in our supply chain and enable As part of the audit process, auditors review suppliers to both mitigate issues and build their documents, observe daily work practices, and social and environmental responsibility (SER) interview supplier management and workers Final assembly suppliers Direct suppliers Sub-tier suppliers capabilities. In addition, we engage our suppliers independently to assess the implementation of in targeted assessments and programs to drive the SER standards in the RBA Code of Conduct. more opportunities for improvement. In FY22, auditors conducted 12,641 confidential High-performing supplier factories We expect our suppliers to adhere to the feedback interviews as part of the audit process. Responsible Business Alliance (RBA) Code Upon the completion of an audit, auditors issue of Conduct. Audits help monitor suppliers’ final reports to identify areas of nonconformance 68% compliance with the RBA Code of Conduct and with the RBA Code of Conduct. The number and highlight any areas of concern, which in turn severity of these audit findings — classified as of factories are high performing based on their audit scores helps Dell work with suppliers to take action and priority, major, minor and risk of nonconformance (at least 180 out of 200 for final assembly factories or 160 to improve their performance. In FY2246, 317 — will impact a supplier’s overall audit score, out of 200 for other factory tiers and no priority findings) factories in our supply chain across 16 countries which ranges from zero to 200. Audit findings underwent audits. can lead to the third and fourth elements of the Typically, our audits are all completed on-site. continuous improvement model: corrective action However, due to the ongoing impact of COVID-19, and capability building. INTRO OUR PLAN GOALS DASHBOARD ADVANCING SUSTAINABILITY CULTIVATING INCLUSION TRANSFORMING LIVES ETHICS & PRIVACY SUPPLY CHAIN BY THE NUMBERS APPENDIX 108

Our purpose in action | Dell Page 107 Page 109

Our purpose in action | Dell Page 107 Page 109