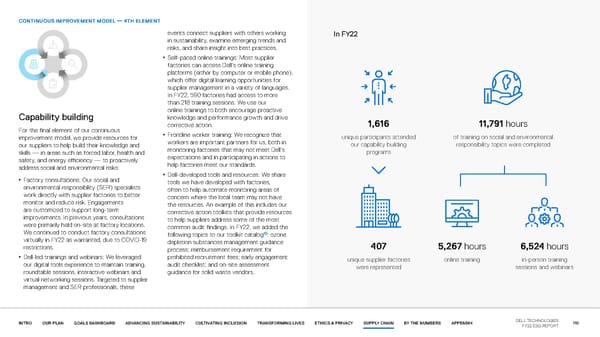

CONTINUOUS IMPROVEMENT MODEL — 4TH ELEMENT events connect suppliers with others working In FY22 in sustainability, examine emerging trends and risks, and share insight into best practices. • Self-paced online trainings: Most supplier factories can access Dell’s online training platforms (either by computer or mobile phone), which offer digital learning opportunities for supplier management in a variety of languages. In FY22, 590 factories had access to more than 218 training sessions. We use our online trainings to both encourage proactive Capability building knowledge and performance growth and drive 1,616 11,791 hours For the final element of our continuous corrective action. improvement model, we provide resources for • Frontline worker training: We recognize that unique participants attended of training on social and environmental our suppliers to help build their knowledge and workers are important partners for us, both in our capability building responsibility topics were completed skills — in areas such as forced labor, health and monitoring factories that may not meet Dell’s programs safety, and energy efficiency — to proactively expectations and in participating in actions to address social and environmental risks: help factories meet our standards. • Factory consultations: Our social and • Dell-developed tools and resources: We share environmental responsibility (SER) specialists tools we have developed with factories, work directly with supplier factories to better often to help automate monitoring areas of monitor and reduce risk. Engagements concern where the local team may not have are customized to support long-term the resources. An example of this includes our improvements. In previous years, consultations corrective action toolkits that provide resources were primarily held on-site at factory locations. to help suppliers address some of the most We continued to conduct factory consultations common audit findings. In FY22, we added the following topics to our toolkit catalog48: ozone virtually in FY22 as warranted, due to COVID-19 depletion substances management guidance restrictions. process; reimbursement requirement for 407 5,267 hours 6,524 hours • Dell-led trainings and webinars: We leveraged prohibited recruitment fees; early engagement unique supplier factories online training in-person training our digital tools experience to maintain training, audit checklist; and on-site assessment were represented sessions and webinars roundtable sessions, interactive webinars and guidance for solid waste vendors. virtual networking sessions. Targeted to supplier management and SER professionals, these INTRO OUR PLAN GOALS DASHBOARD ADVANCING SUSTAINABILITY CULTIVATING INCLUSION TRANSFORMING LIVES ETHICS & PRIVACY SUPPLY CHAIN BY THE NUMBERS APPENDIX DELL TECHNOLOGIES 110 FY22 ESG REPORT

Our purpose in action | Dell Page 109 Page 111

Our purpose in action | Dell Page 109 Page 111