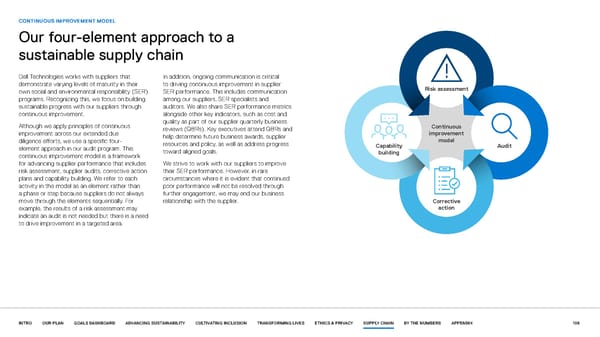

CONTINUOUS IMPROVEMENT MODEL Our four-element approach to a sustainable supply chain Dell Technologies works with suppliers that In addition, ongoing communication is critical demonstrate varying levels of maturity in their to driving continuous improvement in supplier own social and environmental responsibility (SER) SER performance. This includes communication Risk assessment programs. Recognizing this, we focus on building among our suppliers, SER specialists and sustainable progress with our suppliers through auditors. We also share SER performance metrics continuous improvement. alongside other key indicators, such as cost and Although we apply principles of continuous quality as part of our supplier quarterly business reviews (QBRs). Key executives attend QBRs and Continuous improvement across our extended due help determine future business awards, supplier improvement diligence efforts, we use a specific four- resources and policy, as well as address progress model element approach in our audit program. This Capability Audit continuous improvement model is a framework toward aligned goals. building for advancing supplier performance that includes We strive to work with our suppliers to improve risk assessment, supplier audits, corrective action their SER performance. However, in rare plans and capability building. We refer to each circumstances where it is evident that continued activity in the model as an element rather than poor performance will not be resolved through a phase or step because suppliers do not always further engagement, we may end our business move through the elements sequentially. For relationship with the supplier. Corrective example, the results of a risk assessment may action indicate an audit is not needed but there is a need to drive improvement in a targeted area. INTRO OUR PLAN GOALS DASHBOARD ADVANCING SUSTAINABILITY CULTIVATING INCLUSION TRANSFORMING LIVES ETHICS & PRIVACY SUPPLY CHAIN BY THE NUMBERS APPENDIX 106

Our purpose in action | Dell Page 105 Page 107

Our purpose in action | Dell Page 105 Page 107